Services / Spare Parts

Our Services

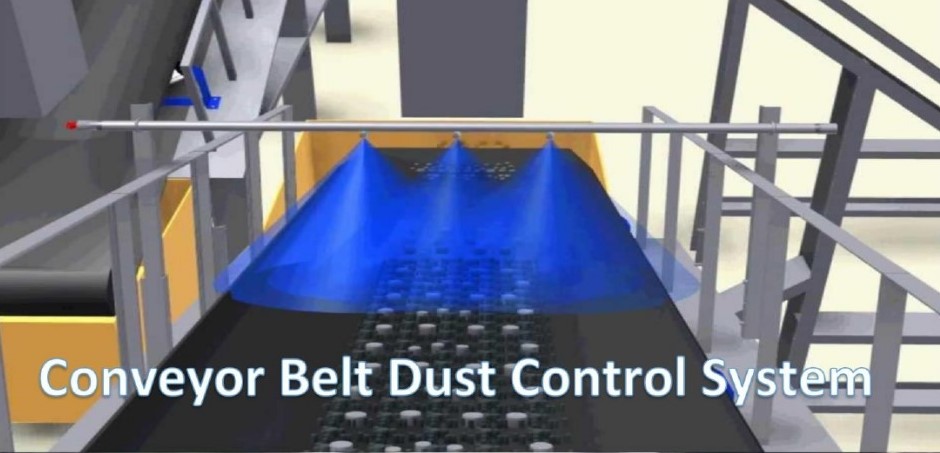

Hemmac offers Conveyor Belt Dust Control System as a Service to help you maintain a clean and safe working environment at your facility. Our comprehensive service includes:

- System Design and Installation: Our experts will design a custom dust control system that meets your specific needs and ensure proper installation for optimal performance.

- System Maintenance: We provide regular maintenance of your dust control system to ensure it continues to operate efficiently and effectively. This includes replacing filters, cleaning ducts, and inspecting all system components.

- System Monitoring: We can remotely monitor your dust control system to identify any potential issues and address them promptly. This helps to prevent downtime and ensures your system is operating at peak performance.

By choosing Hemmac’s Conveyor Belt Dust Control System as a Service, you can benefit from:

- Improved air quality: Our dust control systems effectively capture and remove dust particles from the air, creating a healthier and safer working environment for your employees.

- Reduced maintenance costs: Our regular maintenance services help to prevent costly repairs and extend the life of your dust control system.

- Increased productivity: A clean and healthy work environment can lead to improved employee morale and productivity.

- Peace of mind: With Hemmac managing your dust control system, you can focus on your core business operations and have peace of mind knowing your system is in good hands.

Contact Hemmac today to learn more about our Conveyor Belt Dust Control System as a Service and how we can help you create a cleaner, safer, and more productive work environment.

Here’s how Hemmac’s Hopper Dust Control as a Service benefits you:

- Clear the Air:Significantly reduce dust emissions, creating a healthier and safer work environment for your team and minimizing the impact on the surrounding area.

- Safety First:Improved visibility means safer equipment operation and reduced respiratory risks for your workers.

- Regulation Ready:Stay compliant with local air quality regulations and avoid costly fines.

- Boost Efficiency:Minimize dust-related equipment issues and downtime, keeping your project on track.

- Cost-Effective Solution:Regular maintenance extends the life of your system and avoids expensive repairs.

Don’t let dust cloud your mining or construction project. Hemmac’s Hopper Dust Control as a Service provides a turnkey solution to keep your site clean, safe, and compliant.

- Expert Design & Installation:Our team designs a custom hopper dust control system tailored to your material, volume, and site layout. We then handle the entire installation, ensuring optimal performance.

- Hassle-Free Management:We take care of everything! Regular maintenance includes filter changes, system cleaning, and keeping your dust suppression system running smoothly.

- Remote Monitoring & Peace of Mind:Our remote monitoring system keeps an eye on dust levels and equipment health. We proactively address any issues before they become problems.

Focus on your project, not on dust control. Let Hemmac handle it. Contact us today for a free consultation and see how we can create a cleaner, safer, and more productive work environment for your mining or construction site.

Contact Hemmac Today

Let Hemmac help you create a cleaner, healthier work environment for your employees and comply with environmental regulations. Contact us today to learn more about our Haul Pak Road Sprinkler System and get a quote.

Reduce dust on your haul roads with an automated, high-frequency, light watering system from Hemmac. Our Haul Pak Road Sprinkler System is designed to provide superior dust control without the high labor or equipment costs associated with water tankers.

- Reduced Costs:Minimize ongoing costs associated with dust suppression.

- High Level of Control:Easily adjust application rates and frequencies to meet your specific needs.

- Natural Intermittent/Spaced Watering:Simulate natural rainfall patterns for optimal dust suppression.

- Easy Integration:Integrate seamlessly with your existing mine systems.

- Easy to Expand or Modify:Easily adapt the system to your changing needs.

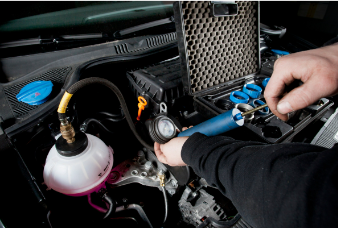

HEMMAC’s Engine Cooling System Expertise:

Our certified technicians can diagnose and address any engine cooling issue, including:

- Coolant System Flush and Refill:We’ll remove old, contaminated coolant and replace it with fresh coolant for optimal heat transfer.

- Radiator Inspection and Cleaning:We’ll thoroughly inspect your radiator for clogs and debris, ensuring proper airflow.

- Thermostat and Sensor Testing:We’ll verify the functionality of your engine’s temperature control system.

- Hose and Belt Replacement:We’ll check for wear and tear on critical cooling system components and replace them as needed.

Is your heavy machinery running hot? Smoke billowing from the engine can be a terrifying sight, and overheating can cause serious, irreversible damage. At HEMMAC, we’re the heavy earth moving machinery service experts you can trust to keep your engines cool and running smoothly.

Challenges of Engine Cooling in Heavy Machinery:

- Extreme Work Conditions:Heavy machinery operates in demanding environments, battling dust, mud, and extreme temperatures. These conditions can clog radiators and reduce cooling efficiency.

- High Engine Loads:Construction and mining equipment work hard, generating immense heat that needs to be effectively dissipated.

- Maintenance Needs:Over time, coolant degrades, and hoses and other components can wear down, impacting cooling performance.

Don’t wait for a breakdown! Schedule your engine cooling system service with HEMMAC today. We’ll keep your heavy machinery running cool and avoid costly repairs down the road.

HEMMAC’s AC Maintenance Advantage:

Our experienced technicians understand the specific demands of heavy machinery AC systems. Our maintenance service includes:

- Detailed inspection:We thoroughly examine all AC components, identifying potential issues before they become major problems.

- Meticulous cleaning:We clean filters, coils, and condensate lines to ensure optimal airflow and prevent overheating.

- Leak detection and repair:We identify and seal refrigerant leaks to maintain cooling efficiency.

- Electrical checks:We ensure all electrical connections are secure and functioning properly.

- Performance optimization:We fine-tune the system for peak performance and energy savings.

At HEMMAC, we’re not just heavy earth moving machinery specialists – we’re also experts in keeping them running cool! Our comprehensive AC maintenance service ensures your equipment maintains optimal operating temperature, preventing breakdowns and maximizing efficiency.

Why is AC maintenance crucial for heavy machinery?

Unlike standard air conditioners, heavy machinery AC systems face unique challenges:

- Harsh environments:Dust, dirt, and debris can quickly clog filters and coils, reducing airflow and cooling capacity.

- Extreme temperatures:Heavy machinery often operates in scorching environments, putting extra strain on the AC system.

- Vibrations:Constant vibrations can loosen electrical connections and damage delicate components.

Don’t let a malfunctioning AC system slow down your operations. Schedule your AC maintenance service with HEMMAC today!

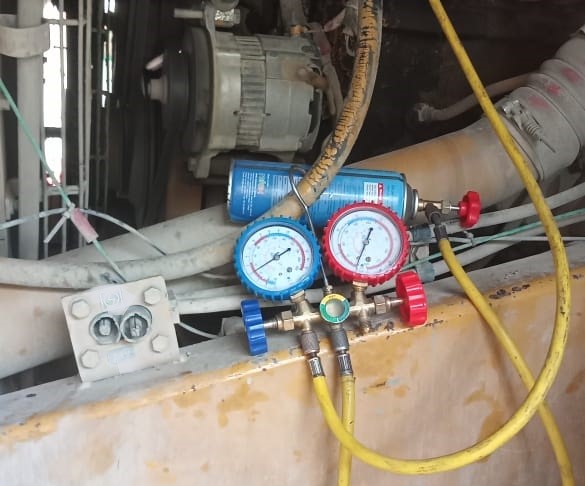

HEMMAC isn’t just about keeping your heavy earth moving machinery operational; we also ensure they perform optimally in any condition. That’s why we offer expert refrigerant service to maintain the efficient cooling of your machine’s critical systems.

Our certified technicians have the knowledge and experience to handle all your refrigerant needs, including:

- Refill and Top-Up:We’ll ensure your machines have the proper refrigerant levels for peak performance.

- Leak Detection and Repair:We’ll pinpoint refrigerant leaks and repair them efficiently to minimize downtime.

- Recovery and Recycling:We responsibly recover and recycle used refrigerants following all environmental regulations.

- Transition to Eco-Friendly Options:We can advise and assist you in switching to environmentally friendly refrigerants as regulations evolve.

Don’t let overheating hinder your projects. Contact HEMMAC today to schedule your refrigerant service and keep your heavy earth moving machinery operating at peak efficiency.

HEMMAC’s Air Conditioning Solutions:

Our team of certified technicians understands the unique challenges of air conditioning in heavy machinery. We offer:

- Durable, Heavy-Duty AC Systems:Built to withstand the rigors of construction sites.

- Expert Installation:Ensuring optimal performance and longevity of your AC unit.

- Preventative Maintenance:Regular cleaning and inspection to prevent costly breakdowns.

- Fast Repairs:Minimize downtime with prompt and efficient AC repair services.

HEMMAC, your one-stop shop for heavy earthmoving machinery service, offers expert air conditioning installation and maintenance to keep your operators cool and productive, even in the harshest conditions.

Challenges of Air Conditioning in Heavy Machinery:

- Harsh Environments:Dust, dirt, and debris can clog filters and damage delicate AC components.

- Extreme Temperatures:Heavy machinery endures scorching heat, demanding robust systems designed for efficient cooling.

- Constant Vibrations:The constant rumble of earthmoving can put stress on AC parts, leading to leaks and malfunctions.

Don’t let the heat sideline your operations!

Contact HEMMAC today to schedule your air conditioning service and keep your earthmoving projects on track.

Our Spares

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

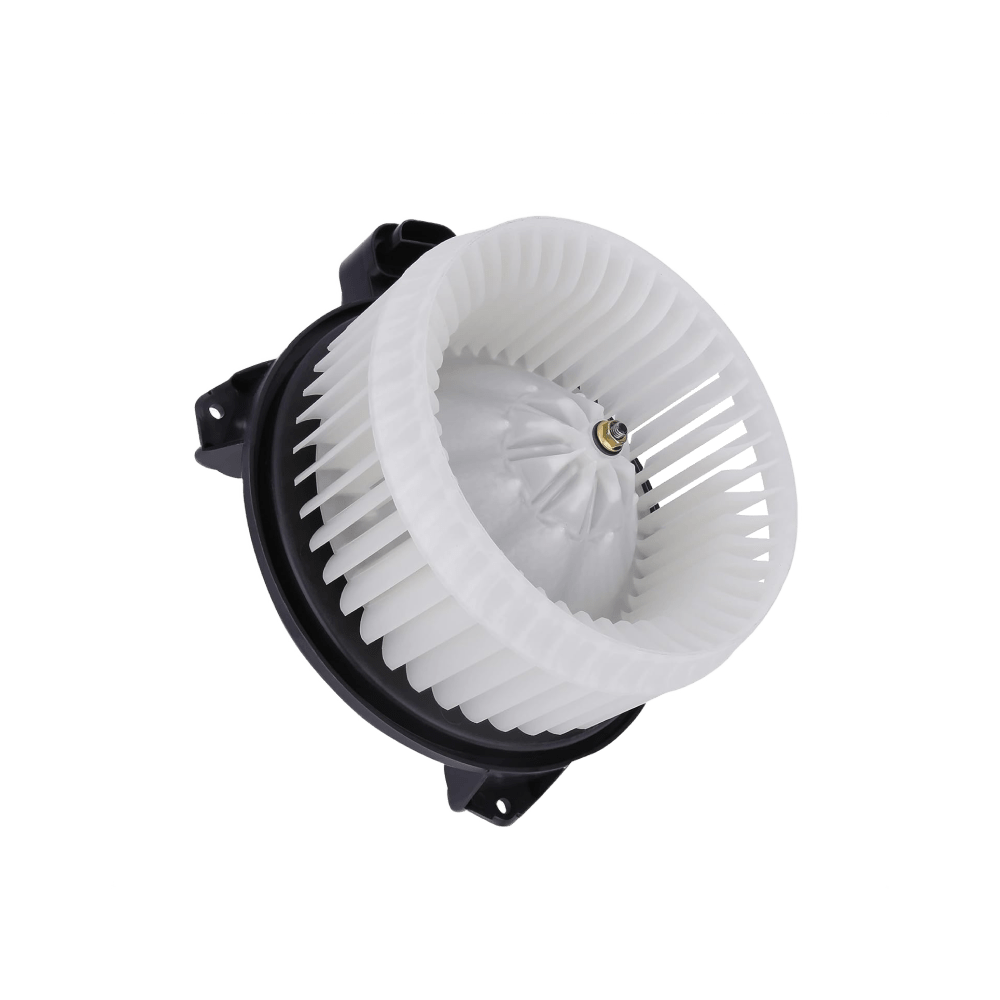

Blower motor

The blower motor is the fan that forces warm or cooled air through the dashboard vents depending on the system settings and the fan speed.

Control panel

An electrical control panel is a metal box which contains important electrical devices that control and monitor a mechanical process.

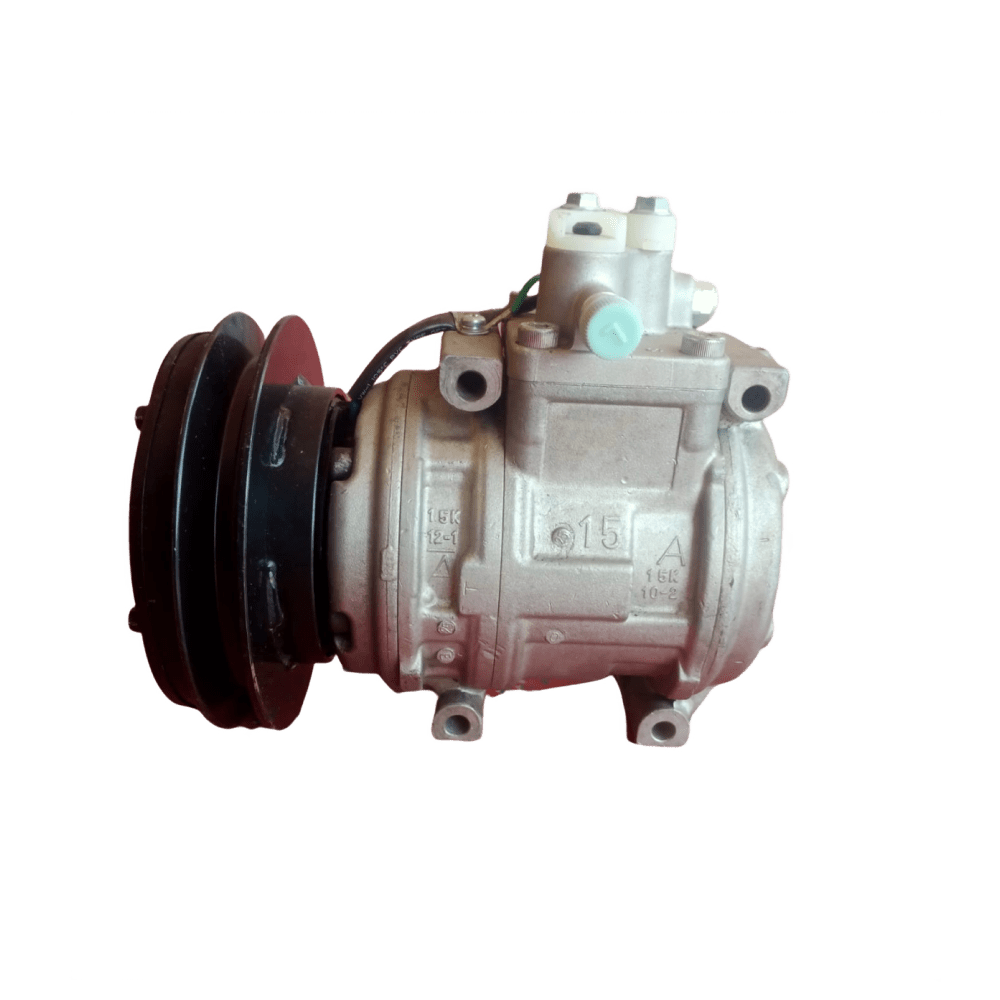

Compressor

The compressor is the key component of the HVAC system that generates high pressure before pumping refrigerant into the condenser, where it transforms from a gas to a liquid.

Evaporator

The evaporator fan motor circulates air through the coils of the evaporator to remove heat from the circulating air. It is a component of the overall refrigeration system.

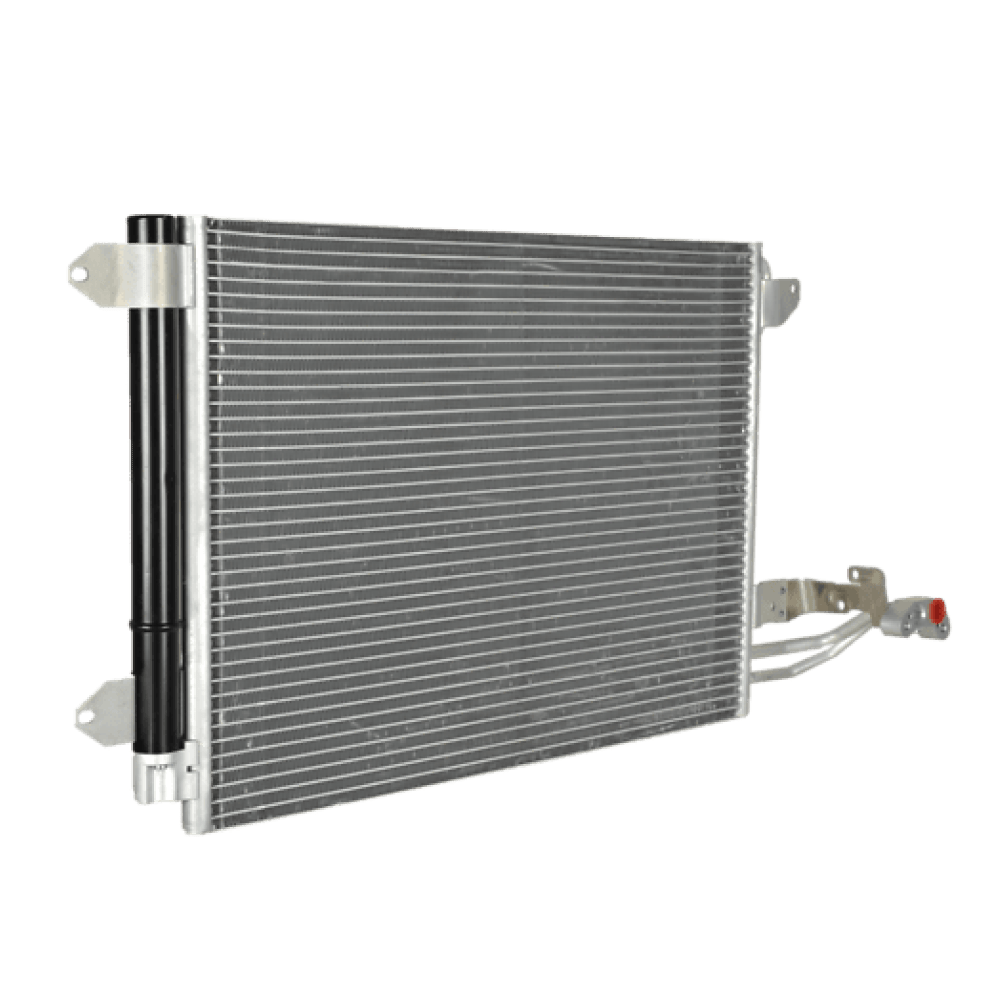

Condenser

The condenser is a heat exchanger.The condenser cools down the refrigerant (heated up by the compressor) and becomes a liquid by transferring its heat to the flow of ambient air passing through it.

Condenser Fan

A condenser fan is found near the condenser. It’s designed to remove heat from the refrigerant inside of the condenser.

Compressor Clutch Assembly

The AC compressor clutch is needed to convert energy to make the compressor work. In simple electromagnetic, or electro-mechanical, clutches, they are operated by electricity but facilitate the mechanical transfer of torque